Products

Products

Dairy Beverage Industry Packages

Coffee And Tea Packaging

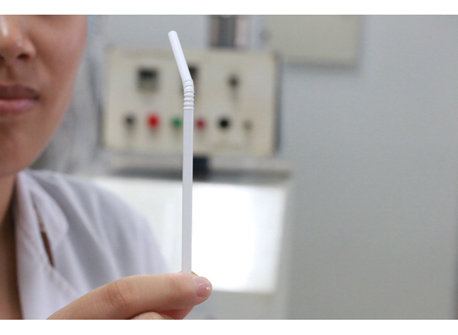

Eco-friendly Products

New Materials

Daily Protection

Innovative R&D

Innovative R&D

Innovative R&D

Contact Us

Contact Us

Contact Us

Lean Production System

Pengli enriches the lean production system matrix continuously, aiming to create value, and achieves the production goal of increasing speed and reducing cost by reducing production process waste, inventory waste, processing waste and transportation waste.

Pengli enriches the lean production system matrix continuously, aiming to create value, and achieves the production goal of increasing speed and reducing cost by reducing production process waste, inventory waste, processing waste and transportation waste.

Through the whole process of equipment management and comprehensive data and target performance management, we continue to carry out the activities of "all staff 5S", "all staff spot inspection", "all staff proposal & improvement", and "all staff energy saving and consumption reduction", so as to realize the rationalization of equipment investment, the standardization of design and installation, the standardization of use and maintenance, the specialization of maintenance and renovation, and the economy of renewal and transformation.

Through the whole process of equipment management and comprehensive data and target performance management, we continue to carry out the activities of "all staff 5S", "all staff spot inspection", "all staff proposal & improvement", and "all staff energy saving and consumption reduction", so as to realize the rationalization of equipment investment, the standardization of design and installation, the standardization of use and maintenance, the specialization of maintenance and renovation, and the economy of renewal and transformation.

Create a comprehensive quality system with "zero defects" to minimize costs and maximize profits.

Create a comprehensive quality system with "zero defects" to minimize costs and maximize profits.

Data standardization is fully applied to create an "agile" workshop and move toward zero inventory.

Data standardization is fully applied to create an "agile" workshop and move toward zero inventory.